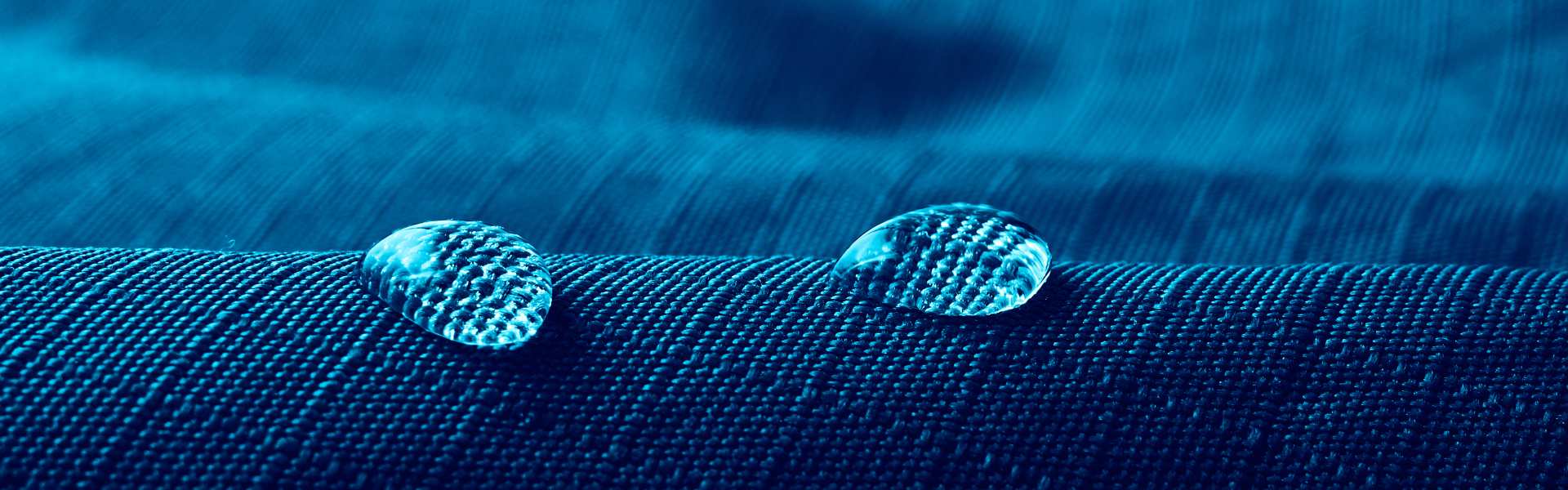

Contemporary uses ofwaterproof waxextend beyond the boundaries and impact of its traditional applications. Consider Otter Wax - a simple fabric wax that renders canvas waterproof in under one hour, causing water to bead up and roll off instead of soaking through. Waterproof wax has transformed outdoor gear, turning ordinary canvas into a durable, water-resistant material. This versatile substance has stood the test of time, from military rucksacks and sails to modern boots, wood protection, and leather treatment applications. Understanding howwaterproof waxis made is key to choosing the right product.

Understanding the manufacturing process is crucial for selecting the appropriate product. Let’s explore the production method ofwaterproof wax, uncover its essential ingredients, and see how different formulations serve specific purposes.

Quality ingredients are the foundation of awaterproof waxthat works. Unlike regular waxes, these specialised formulas blend specific components to create a hydrophobic barrier against moisture.

The efficacy of awaterproof waxdepends on the right balance of ingredients, which manufacturers adjust based on application and environmental conditions.

Waterproof waxproduction requires precision to turn raw materials into moisture barriers that work. Today's industry relies on three main manufacturing approaches:

The water-in-wax method starts by melting wax components and adding hot water with emulsifiers. A thorough mixing follows. This approach gives the best results with lower melting point waxes.

The wax-in-water technique follows a different path. It begins by melting wax with one emulsifier before adding it to hot water containing extra emulsifiers and additives.

Leather waterproof wax manufacturers typically use double boilers to melt ingredients safely. This indirect heating prevents overheating and reduces fire risks since many wax components have low flash points. Modern facilities use sous-vide circulators at specific temperatures (around 70°C) to keep wax from burning or changing colour.

The properly melted waterproof wax can be applied to boots and other items through various techniques:

The efficacy of boot wax depends heavily on the curing process. Items need heating after application to bond the wax with the material fibres. Hair dryers, heat guns, or specialised equipment can accomplish this heating. Optimal water resistance occurs when drying temperatures remain below the wax's melting point.

Wood waterproof wax and other specialised products undergo rigorous water resistance testing. This includes hydrostatic head tests, which measure water penetration resistance under pressure, and spray tests, which check surface wetting.

When finishing, industrial manufacturers often combine waterproofing with colour pigmentation, allowing dyeing and waterproofing to co-occur. Traditional waterproof waxes remain popular among other synthetic alternatives. Their breathability, easy repairs, and classic look make them a preferred choice.

Different materials require specialised waterproof wax formulations to provide optimal protection and performance. A wax that works beautifully for leather might not work well for canvas or wood.

Manufacturers often blend beeswax with lanolin and essential oils to create a resilient, waterproof boot wax for leather goods. This combination repels water and conditions the material at the same time. Leather loses vital tanning agents as it absorbs water, which causes stiffening and reduced durability. Quality leather waterproof wax replenishes these tanning agents and maintains the leather's structure without over-softening.

Canvas protection has come a long way since Scottish fishermen used linseed oil to waterproof sails in the 1800s. Modern canvas wax formulations include:

Some manufacturers now produce petroleum-free alternatives that appeal to environmentally conscious consumers. To illustrate, Otter Wax offers "the first and only water-repellent wax that doesn't use paraffin, silicone, or other petroleum-based synthetic ingredients."

Waterproof wax for wood requires completely different considerations. These formulations mix coconut oil and beeswax to protect wood's natural beauty. These specialised waxes create a durable moisture barrier, enhancing wood's natural colour and adding subtle shine.

A pattern emerges in these formulations—natural waxes create protective barriers, while oils seep into the material to condition from within. Each product's efficacy depends on the precise balance of ingredients for its intended use.

All material types require proper curing after application. Waxed leather should not be machine-washed or exposed to extreme heat. The same goes for waxed canvas, which needs gentle spot cleaning instead of machine washing that strips away the protective coating.

Waterproof wax is an impressive blend of natural and synthetic ingredients that creates substantial moisture barriers. This versatile substance protects everything from leather boots to wooden surfaces and canvas materials. Each unique formula works differently because of its balanced components.