We often associate wax withcandles, furniturepolish, and surfing, but its versatility extends far beyond these everyday uses.Wax coatingsplay a crucial role in various industrial and commercial sectors, offering protection, enhancement, and functionality across a wide range of materials. From packaging and textiles to machinery and food products,wax coatingsprovide unique benefits that improve durability, resistance, and sustainability.

In this article, we examine the various types ofwax coatingsemployed in industry, their key applications in commercial sectors, the performance advantages and limitations they offer, and their overall impact. Let's delve into the world ofwax coatingsand uncover their potential.

The term "wax coating" encompasses a range of formulations, each with distinct properties and tailored to meet specific industrial requirements. Some of the most common types include:

Each type of wax brings something special to coating applications. You might require microcrystalline's flexibility or carnauba's hardness. Your industrial application's performance requirements will help you choose the right option.

Wax coatings offer a versatile solution for various commercial and industrial needs. Some of the key applications include:

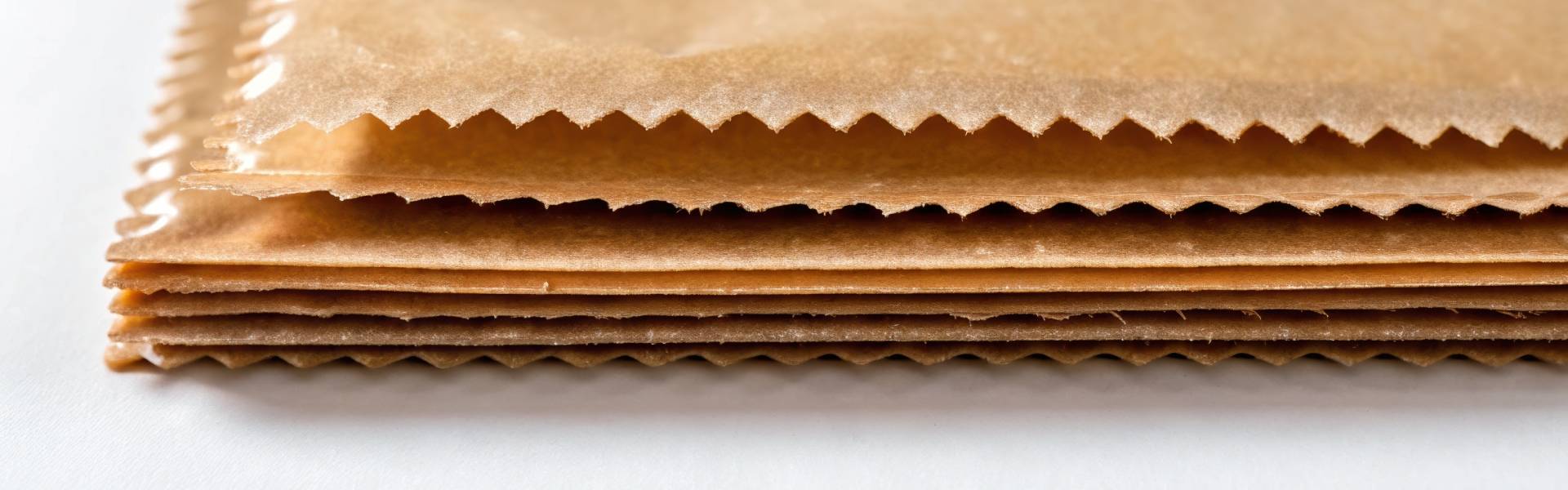

Wax coatings are widely used in the food and beverage industry for packaging applications. They provide a moisture barrier, prevent spoilage, and enhance the appearance of products. Wax-coated paper cups, cartons, cheese coatings, fruit preservatives and wrappers are common examples. They also extend shelf life and improve product presentation. Modified paraffin wax helps prevent mould growth during cheese ageing.

Wax coatings are applied to printed materials, such as brochures, magazines, and labels, to enhance gloss, protect against abrasion, and improve water resistance. They also improve adhesion in printing applications.

Wax finishes are used on furniture, floors, and other wood surfaces to protect them from moisture, scratches, and stains. They also enhance the natural beauty of the wood. Woodworkers use wax as their final step to add lustre and hide minor imperfections in the finish. Its slippery feel and moderate sheen work perfectly for items that don't face excessive handling.

Wax coatings reduce corrosion, improve lubrication, and enhance shine in vehicles and industrial equipment. Products like 3M™ Synthetic Wax Protectant create protective layers by bonding chemically to vehicle surfaces and resist moisture for up to six months. Hardwax creates flexible barriers that prevent electrochemical oxidation on metal surfaces, delivering superior corrosion protection.

Wax coatings can provide a barrier against corrosive agents, protecting metal surfaces from rust and degradation. They are used in automotive, marine, and industrial applications. Aerospace companies use elite waxes to form carbon fibre and create fine metal components. Marine industry professionals trust wool-wax formulations that have protected against highly corrosive environments for more than fifty years.

Wax coatings provide water resistance and durability in fabrics, footwear, and leather goods.

Wax is a key ingredient in many cosmetic products, including lipsticks, lotions, and creams. It provides emolliency, texture, and protection to the skin.

Plant-based wax coatings are emerging as sustainable alternatives for recyclable and biodegradable packaging solutions.

The success of a wax coating depends on how it is made and applied. Tests show that paper coated with beeswax blocks water vapour much better, cutting transmission by 77% compared to plain surfaces. This water-repellent quality makes these coatings ideal for use with moisture-sensitive materials.

The mechanical benefits of wax coatings are impressive, too. Beeswax mixtures boost tensile strength by 26% and elastic modulus by 46%. The coated papers might stretch less before breaking, but they end up stronger overall.

Wax coatings offer a range of benefits that make them attractive for various applications:

However, wax coatings also have some limitations:

Wax coatings provide a versatile and cost-effective solution for a wide range of industrial and commercial applications, striking a balance between performance and sustainability. From protecting food packaging to enhancing the appearance of printed materials, wax coatings provide numerous benefits. While they have some limitations, careful selection of the appropriate wax type and application method can maximise their performance and ensure long-lasting protection. As industries continue to seek sustainable and cost-effective solutions, wax coatings are poised to play an increasingly important role in protecting and enhancing the products we use every day. By understanding the various types of waxes and their distinct properties, businesses can make informed decisions about how best to utilise these versatile materials for their specific needs.